Goodbye petrol, hello electric power unit. Carsten Krebs is upbeat about the prospects for vehicle manufacture: “In the not too distant future, the car will be our best friend.” Krebs is press officer at Volkswagen’s Gläserne Manufaktur (Transparent Factory) which, simultaneously with the plant in Los Angeles, recently launched the brand new e-Golf with a lithium-ion battery. By Stefanie Maeck

The car of the future will not only be electric

But the enthusiasm is heartfelt: “E‑mobility is the way forward,” says Krebs as he takes us on a tour of the exhibition ‘Fahren von morgen’ (Tomorrow’s Driving) in the Transparent Factory. You can find out what he means on a test drive through the streets of Dresden. The car of the future will not only be electric but also digital: when the driver gets into the cockpit, the apps on his or her smartphone will be displayed on the dashboard.

There is a realistic prospect of the contents of the fridge at home being shown by the on-board computer. Cameras integrated into the steering wheel will soon be able to detect the driver’s eye movement, allowing him or her to switch radio channels. And as for the sunroof, we will presumably open it with a mere wave of the hand.

Lightweight construction is a key technology for e-mobility.

Niels Modler, Professor at the Institute for Lightweight Engineering and Polymer Technology of TU Dresden (ILK) and runs the largest department for Lightweight Construction in the whole of Europe.

Future modes of transport will be environmentally friendly and sparing in their use of natural resources thanks to intelligent sensors, lightweight materials, new technologies and high-performance batteries. This is what is keeping researchers busy in the various institutes based in the city. Niels Modler is one of them. He is a professor at the Institute for Lightweight Engineering and Polymer Technology of TU Dresden (ILK) and runs the largest department for Lightweight Construction in the whole of Europe. Approximately three kilometres away from the Transparent Factory, he and his colleagues are trying to find out how electric cars can be made to weigh less. They are looking into so-called ‘sandwich materials’, i.e. a covering layer of steel over a fibre composite core which combines the advantages of both components to produce a lightweight vehicle body. “Ultra-lightweight cars save on fuel,” explains Modler.

Working in collaboration with the Fraunhofer Institute for Material and Beam Technology (IWS), his team has recently succeeded in developing a hybrid of textile thermoplastic and metal. In a joint project with Thyssenkrupp, they have looked at the potential of a steel and carbon mix and managed to get the weight of a prototype car down to less than 900 kilos. “Lightweight construction is a key technology for e-mobility,” adds Modler. Dresden has gained an international reputation as a research hub for lightweight technology, especially since the establishment of the Research Center Carbon Fibers Saxony (RCCF), which focuses on the development of carbon fibres that have the capacity to revolutionise lightweight construction. Modler is able to draw on input from innovative researchers at other institutes, a bonus which he calls “the Dresden spirit”.

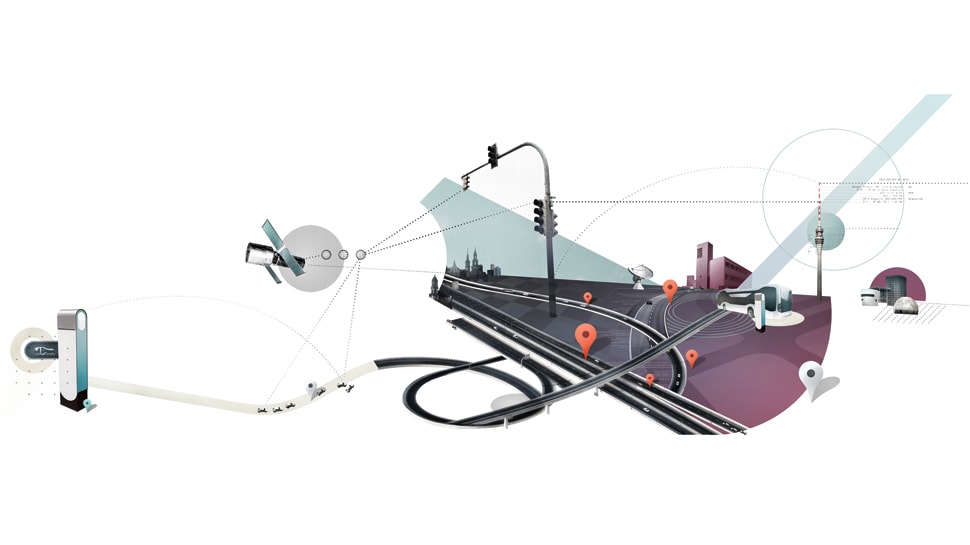

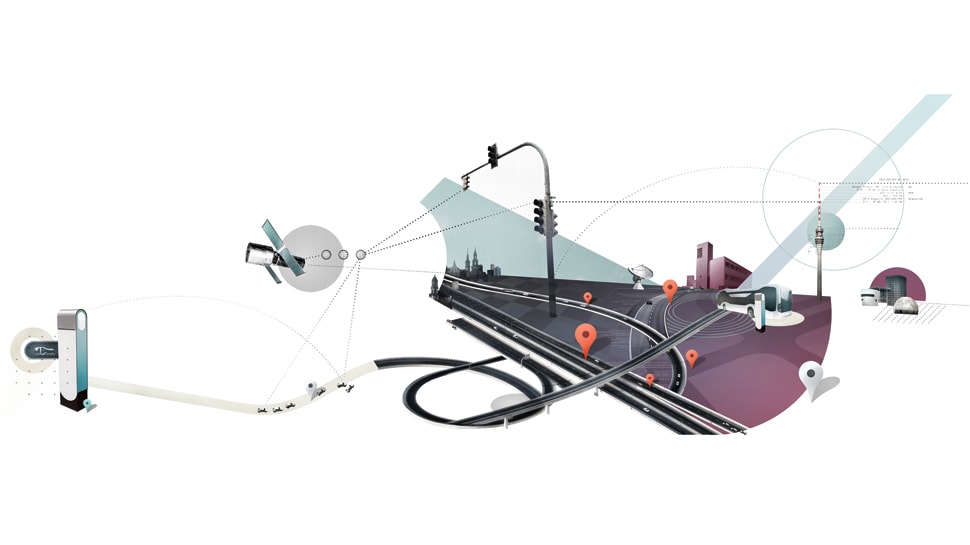

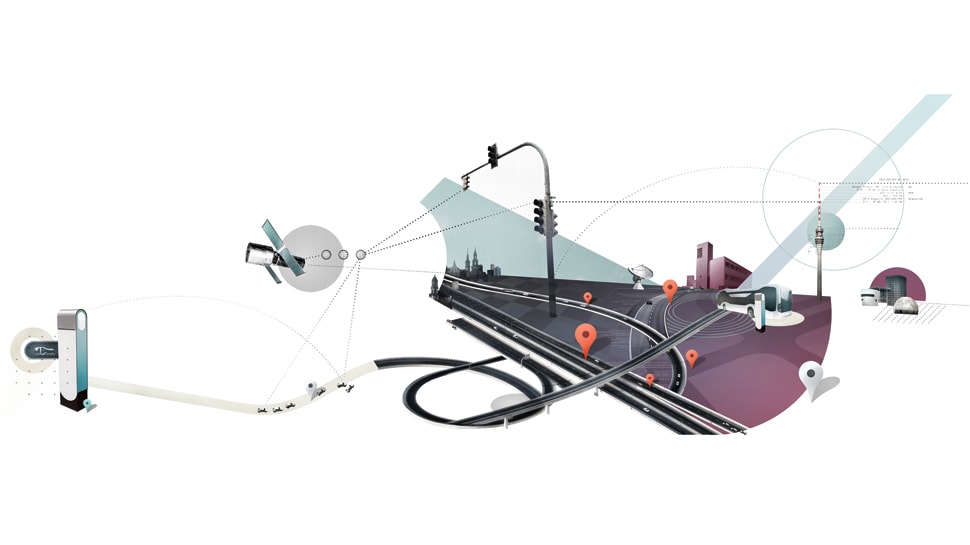

Driverless cars could appear on the streets of Dresden sooner than many people think. Parking sensors in the car are connected to a central computer, which then informs other drivers about available spaces. According to the research department at VW, robot taxis or autonomous vehicles that drive in convoy along the motorways and brake and accelerate by themselves could become a reality by 2020. They have given a name to this vision of the future: Modellstadt Elektromobilität (Model city: e-mobility). The city police are already pioneering the concept in electric patrol cars. Meanwhile, the municipal transport services in Dresden have switched some of their buses to lightweight and quiet-running carbon-fibre aluminium rims and can’t wait for the new technology to go into series production.

Institute for Lightweight Engineering and Polymer Technology (ILK)

At ILK, 250 employees are working on projects in the field of lightweight construction. They come from different academic backgrounds, including mechanical engineering, materials science and electrical engineering.

tu-dresden.de

The Transparent Factory

VW plans to produce models in the premium and luxury segment in addition to electrically powered vehicles at its Gläserne Manufaktur factory in Dresden.

glaesernemanufaktur.de

Lesen Sie auch …

-

Augustus the Strong had great plans for0 his son. 300 years ago, he laid on the biggest wedding party ever.

-

1719 reloaded – Dresden commemorates the wedding of the century with numerous events, exhibitions, performances and festivities.

-

A foundling comes of age Heinemann had the necessary self-belief because he had been working at Robotron since the late 1960s. He…

Goodbye petrol, hello electric power unit. Carsten Krebs is upbeat about the prospects for vehicle manufacture: “In the not too distant future, the car will be our best friend.” Krebs is press officer at Volkswagen’s Gläserne Manufaktur (Transparent Factory) which, simultaneously with the plant in Los Angeles, recently launched the brand new e-Golf with a lithium-ion battery. By Stefanie Maeck

The car of the future will not only be electric

But the enthusiasm is heartfelt: “E‑mobility is the way forward,” says Krebs as he takes us on a tour of the exhibition ‘Fahren von morgen’ (Tomorrow’s Driving) in the Transparent Factory. You can find out what he means on a test drive through the streets of Dresden. The car of the future will not only be electric but also digital: when the driver gets into the cockpit, the apps on his or her smartphone will be displayed on the dashboard.

There is a realistic prospect of the contents of the fridge at home being shown by the on-board computer. Cameras integrated into the steering wheel will soon be able to detect the driver’s eye movement, allowing him or her to switch radio channels. And as for the sunroof, we will presumably open it with a mere wave of the hand.

Future modes of transport will be environmentally friendly and sparing in their use of natural resources thanks to intelligent sensors, lightweight materials, new technologies and high-performance batteries. This is what is keeping researchers busy in the various institutes based in the city. Niels Modler is one of them. He is a professor at the Institute for Lightweight Engineering and Polymer Technology of TU Dresden (ILK) and runs the largest department for Lightweight Construction in the whole of Europe. Approximately three kilometres away from the Transparent Factory, he and his colleagues are trying to find out how electric cars can be made to weigh less. They are looking into so-called ‘sandwich materials’, i.e. a covering layer of steel over a fibre composite core which combines the advantages of both components to produce a lightweight vehicle body. “Ultra-lightweight cars save on fuel,” explains Modler.

Working in collaboration with the Fraunhofer Institute for Material and Beam Technology (IWS), his team has recently succeeded in developing a hybrid of textile thermoplastic and metal. In a joint project with Thyssenkrupp, they have looked at the potential of a steel and carbon mix and managed to get the weight of a prototype car down to less than 900 kilos. “Lightweight construction is a key technology for e-mobility,” adds Modler. Dresden has gained an international reputation as a research hub for lightweight technology, especially since the establishment of the Research Center Carbon Fibers Saxony (RCCF), which focuses on the development of carbon fibres that have the capacity to revolutionise lightweight construction. Modler is able to draw on input from innovative researchers at other institutes, a bonus which he calls “the Dresden spirit”.

Driverless cars could appear on the streets of Dresden sooner than many people think. Parking sensors in the car are connected to a central computer, which then informs other drivers about available spaces. According to the research department at VW, robot taxis or autonomous vehicles that drive in convoy along the motorways and brake and accelerate by themselves could become a reality by 2020. They have given a name to this vision of the future: Modellstadt Elektromobilität (Model city: e-mobility). The city police are already pioneering the concept in electric patrol cars. Meanwhile, the municipal transport services in Dresden have switched some of their buses to lightweight and quiet-running carbon-fibre aluminium rims and can’t wait for the new technology to go into series production.

Institute for Lightweight Engineering and Polymer Technology (ILK)

At ILK, 250 employees are working on projects in the field of lightweight construction. They come from different academic backgrounds, including mechanical engineering, materials science and electrical engineering.

tu-dresden.de

The Transparent Factory

VW plans to produce models in the premium and luxury segment in addition to electrically powered vehicles at its Gläserne Manufaktur factory in Dresden.

glaesernemanufaktur.de

Lesen Sie auch …

Augustus the Strong had great plans for0 his son. 300 years ago, he laid on the biggest wedding party ever.

1719 reloaded – Dresden commemorates the wedding of the century with numerous events, exhibitions, performances and festivities.

A foundling comes of age Heinemann had the necessary self-belief because he had been working at Robotron since the late 1960s. He…